A battery charge cycle describes the voltage and current relationship in a battery as the charger returns the energy capacity to the battery. Different battery chemistries, such as lead acid, Ni-Cad, etc. require different methods of charging. The two charging cycles described below, the maintenance charging cycle and the three state charging cycle, are for lead-acid batteries.

Maintenance type chargers are useful in applications such as battery storage and where there is no requirement to return 100% of the battery capacity by the maintainer.

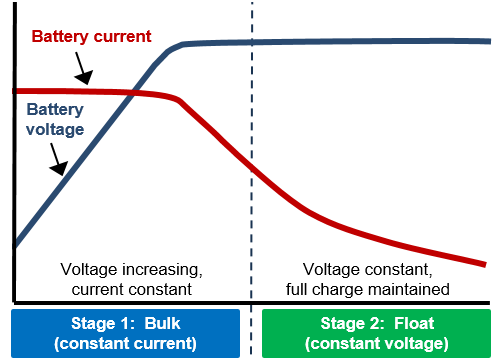

The Chargetek 150 is a maintenance charger. Maintenance type chargers are useful in applications such as battery storage and where there is no requirement to return 100% of the battery capacity by the maintainer. Maintenance chargers are often used where the primary charging source, such as an alternator, is used infrequently. The battery charge is maintained over the long term by the maintenance charger. Please refer to the figure below.

Stage 1: Constant current charging or bulk charge mode

Assuming the battery is starting in a discharged state, the charger is operating in constant current mode, where the charger current is maintained at a constant value and the battery voltage is allowed to rise as it is being recharged. Approximately 80% of battery capacity is returned in the constant current region.

Stage 2: Float mode

The Float mode follows the constant current mode. Float mode is where the battery voltage is maintained at approximately 2.25 volts per cell, or 13.5 volts for a 12V battery. This charger will maintain the battery indefinately without boiling out electrolyte or overcharging the battery.

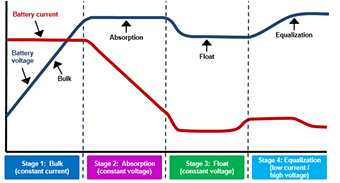

Three stage charging is the method most lead acid battery manufacturers recommend as the best and most efficient way to return full capacity to the battery and extend battery life. All Chargetek lead acid chargers except the CT150 (which is a maintenance charger) are three stage chargers and return full capacity. Please refer to the figure below.

Stage 1: Constant current charging or bulk charge mode

Assuming the battery is starting in a discharged state, the charger is operating in constant current mode, where the charger current is maintained at a constant value and the battery voltage is allowed to rise as it is being recharged. Approximately 80% of battery capacity is returned in the constant current region.

Stage 2: Absorption mode

When the battery voltage reaches approximately 2.4 volts per cell, or 14.6 volts for a 12V battery, the charger voltage is held constant at this level and the battery current is allowed to reduce. It is this region where the last 20% of battery capacity is returned. This voltage level is maintained until the battery current reduces to approximately C/50 to C/100, where C is the amp-hour rating of the battery. For instance, if it is a 100 amp-hour battery, the voltage should be maintained at 2.5V per cell until the current decreases to 1-2 amps. The exact amount is not usually critical.

Stage 3: Float mode

At the point where the current is reduced to C/50 to C/100, the battery charger enters float mode. Float mode is where the voltage on the battery is maintained at approximately 2.25 volts per cell, or 13.5 volts for a 12V battery. This voltage will maintain the full charge condition in the battery without boiling our electrolyte or overcharging the battery.

Four stage charging supplies constant current to battery until absorption voltage is reached (VFSTERM). Transition to absorption mode follows and regulates battery voltage at VFSTERM until current decreases to IABTERM. Float mode follows and regulates battery voltage at VFL. At the user's discretion, an equalization mode can be initiated.

Stages 1, 2, and 3: see the descriptions above under three stage charging cycle

Stage 4: Equalization mode

The purpose of the equalization mode is to remove the sulphation from the lead plates and to eliminate the stratification of the electrolyte. Approximately 2.5-2.6 volts per cell is applied to the battery with the charging current set to a very low value, typically less than 0.5 amp. The equalization mode may last anywhere from a few hours to over 24 hours depending upon circumstances.

For more information about equalization and desulphation, see this presentation.

Chargetek, Inc. 1860 Eastman Avenue Unit 109 Ventura, CA 93003 Phone: (805) 482-7930 Fax: (805) 482-7936 www.chargetek.com |

||||

| Home | Product overview | CK & CT 150 | Custom chargers | |

| About | Product selector guide | CT 500 | Rapid charging technology | |

| Sales inquiries | Battery charger basics | DPIC | Waterproof battery chargers | |

| Contact | Choosing a charger | RTIC-WP | Fan cooled battery chargers | |

| Sitemap | Charging system configurations | RTIC-FC | AC/DC battery chargers | |

| Glossary | TPRO | DC/DC battery chargers | ||

| FAQs | APLC | Lithium battery chargers | ||

| DPLC | ||||

| © 2015 Chargetek, Inc. | ||||